35-50

Learn about the benefits of Ultra Thin Lift Overlay Treatments

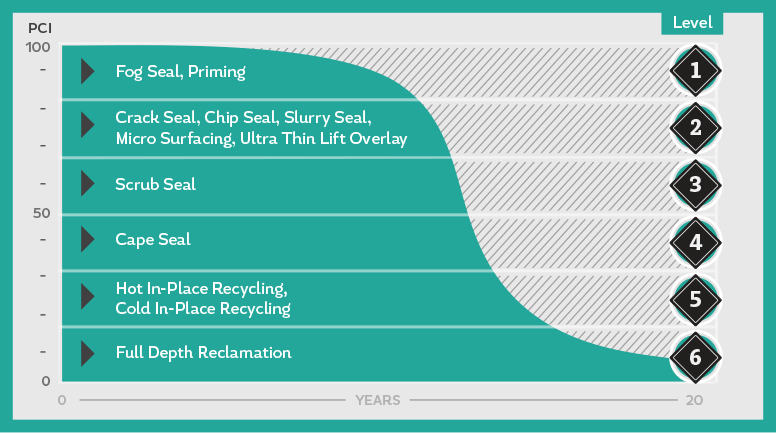

Applying a fresh coat of paint is a simple, cost-effective way to repair minor aesthetic issues on a house. Ultra thin lift overlays provide a similar benefit for roads. Ultra thin lift overlays address functional problems as part of pavement preservation, as opposed to increasing the overall strength of a pavement structure. This treatment is recognized as surface mixes of 1.0” or less compacted-thickness used as part of a simple overlay or as part of a mill and fill operation.

At an average cost of $4.00 per square yard, ultra thin lift overlays allow for an increase in the lifespan of any type of roadway by roughly 8-10 years for a low life-cycle cost. They also can be recycled, restore skid resistance and be quickly placed to provide a quiet, smooth roadway that can handle heavy traffic. By treating minor distresses, the cost of road upkeep is far lower than waiting until a major rehabilitation is needed.

If unsealed cracks larger than a quarter inch or ruts greater than a half inch are present, a ultra thin lift overlay is not sufficient and other treatments may be needed.

Best Practices

- Use a prepared mix design.

- Clean pavement prior to beginning operation.

- Seal cracks larger than ¼”.

- Apply proper bond coat.

- Assure the mix is at a proper temperature.

- Establish and follow roller pattern.

- Allow the mat to cool prior to returning traffic to the road.

Download Success Stories

- Success Story: Claiborne County, TN

Ultra Thin Lift Overlay